In the field of industrial machinery, hydraulic cylinders play an important role, providing the force needed to lift, push, pull, and perform a myriad of other actions. When it comes to choosing the right type of cylinder for an application, understanding the differences between single and double acting cylinders is crucial. Here, we explore the advantages of each type and highlight why industrial hydraulic cylinder manufacturers continue to innovate in this space.

Single-Acting Cylinders

Single-acting cylinders are designed to provide force in one direction only. They use hydraulic pressure to extend the piston, while the retraction is typically handled by an internal spring or external force like gravity.

Advantages of Single-Acting Cylinders:

Simplicity and Cost-Effectiveness: Single-acting cylinders are simpler in design compared to their double-acting counterparts. This simplicity translates to lower manufacturing costs and easier maintenance, making them an economical choice for many applications.

Compact Design: The fewer components involved in single-acting cylinders mean they can be more compact, making them ideal for applications where space is limited.

Reduced Energy Consumption: Since they only use hydraulic power in one direction, single-acting cylinders can be more energy-efficient, which is beneficial for applications requiring repetitive actions like clamping, positioning, or ejecting parts.

Applications: These cylinders are commonly used in lifting equipment, hydraulic presses, and any situation where a single-direction force is sufficient.

Double-acting cylinders

Double-acting cylinders provide force in both directions. They have two ports for hydraulic fluid – one for extending the piston and another for retracting it.

Advantages of Double-Acting Cylinders:

- Versatility: Double-acting cylinders are highly versatile and can be used in a wide range of applications. Their ability to exert force in both directions makes them suitable for tasks requiring precise control and movement, such as in robotics and automated systems.

- Greater Control: The bidirectional nature of double-acting cylinders offers superior control over the movement and positioning of the piston. This control is essential in applications requiring high precision.

- Enhanced Force Capability: These cylinders can exert force in both the extension and retraction strokes, which is crucial for tasks that demand substantial pushing and pulling forces.

- Applications: Double-acting cylinders are widely used in construction equipment, industrial automation, manufacturing machinery, and anywhere that requires consistent and controlled movement in both directions.

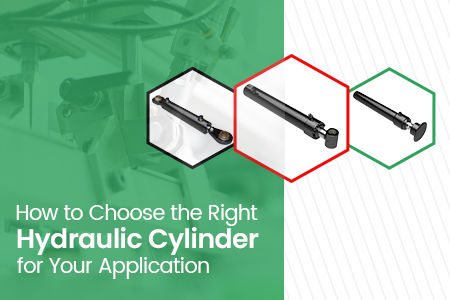

Single-Acting vs. Double-Acting Hydraulic Cylinders

When comparing single-acting vs. double-acting hydraulic cylinders, it's important to consider the specific requirements of your application. Single-acting cylinders are ideal for simple, cost-effective solutions where force is only needed in one direction. On the other hand, double-acting cylinders offer enhanced versatility and control, making them suitable for more complex tasks.

Hydraulic Cylinder Market and Industrial Manufacturers

The hydraulic cylinder market is continually evolving, driven by advancements in technology and the growing demand for efficient and reliable hydraulic systems. Industrial hydraulic cylinder manufacturers like Bicelli Geco are at the forefront of this innovation, providing high-quality solutions that meet the diverse needs of various industries.

While both single-acting and double-acting cylinders have their unique advantages, double-acting cylinders stand out due to their superior versatility, control, and force capabilities. These attributes make them the preferred choice for more complex and demanding industrial applications. As the hydraulic cylinder market continues to grow, staying informed about these options will help you make the best choice for your needs, ensuring the efficiency and performance of your machinery. In comparison, for applications that require more precise and controlled movements, double-acting cylinders offer unparalleled advantages, making them the optimal choice in many industrial scenarios.