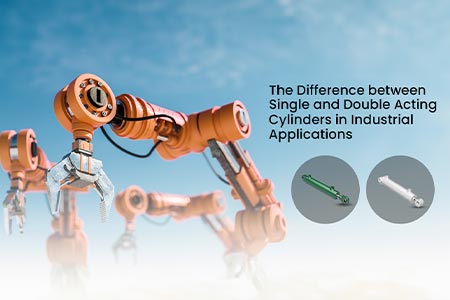

Bicelli Geco, a leading distributor of industrial hydraulic cylinders, understands the critical role hydraulic cylinders play in various applications. Within this realm, two primary types reign supreme: single acting and double acting hydraulic cylinders . But how do they differentiate themselves, and which one best suits your project's needs?

Single Acting Hydraulic Cylinders

Single acting cylinders, the dependable workhorses of the hydraulic world, boast a straightforward and reliable design. They feature a single fluid inlet port and rely on a spring or external force (like gravity) to retract. This makes them perfect for applications requiring force in just one direction, such as:

- Simple lifting and positioning tasks

- Clamping applications

- Punching motions

Advantages of Single Acting Cylinders:

- Straightforward Design: Translates to lower costs and less susceptibility to maintenance issues.

- Efficiency: Effective for specific pushing applications where only single-direction force is needed.

Considerations of Single Acting Cylinders:

- Limited Functionality: Only extends with hydraulic pressure and relies on external force for retraction, which can be slow and uncontrolled.

Double Acting Hydraulic Cylinders

Double acting hydraulic cylinders offer a more versatile solution. These cylinders boast two fluid ports, enabling both extension and retraction under hydraulic power. This translates to:

- Precise Control: Over movement in both directions.

- Faster Actuation: Speeds for both extension and retraction.

- Versatility: Ability to handle both pushing and pulling applications.

Benefits of Double Acting Cylinders:

- Enhanced Control and Flexibility: Double acting hydraulic cylinders Provide superior control and flexibility in various applications.

- Efficient Operation: Faster and more efficient for operations requiring quick, precise movements.

- Ideal for Diverse Applications: Suitable for pushing and pulling applications, making them a versatile choice for many industrial tasks.

Considerations of Double Acting Cylinders:

- Complex Design: Double acting hydraulic cylinders can lead to higher costs and increased potential for maintenance needs due to additional components.

Why Double Acting Cylinders Stand Out

While single acting cylinders have their place in specific applications, double acting cylinders stand out as the best option for many industrial uses. Their ability to provide controlled force in both directions makes them ideal for more complex and demanding tasks. The versatility, enhanced control, and efficiency of double acting cylinders make them the preferred choice for applications requiring precision and reliability.

Selecting the Perfect Cylinder for Your Needs

As a trusted supplier of hydraulic cylinders from leading manufacturers, Bicelli Geco is here to assist you in finding the ideal solution. Our team of experts will evaluate your specific needs and recommend the most suitable cylinder for your application. Whether you need the simplicity of a single acting cylinder or the advanced capabilities of a double acting cylinder, we ensure you get the best performance and value for your investment.

In conclusion, double acting cylinders, with their superior versatility and control, emerge as the best option for industrial applications demanding high precision and efficiency. Trust Bicelli Geco to guide you in selecting the right hydraulic cylinder for your needs.

Contact Bicelli GECO today to discuss your hydraulic cylinder requirements and experience the Bicelli GECO difference!