Customized hydraulic cylinders are engineered to meet specific requirements of individual applications, offering tailored solutions to address unique challenges and performance criteria. These cylinders are designed and manufactured to precise specifications, providing flexibility and adaptability in a wide range of industrial settings.

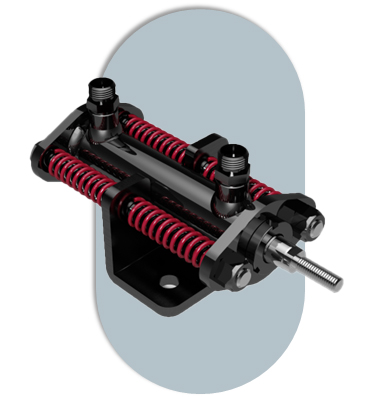

Customized hydraulic cylinders are crafted to precise specifications, allowing for variations in bore size, rod diameter, stroke length, mounting options, and other critical parameters based on the specific needs of the application.

Manufacturers work closely with customers to understand the unique demands of their applications, ensuring that the customized hydraulic cylinders are designed to perform optimally under specific operating conditions.

The choice of materials for customized cylinders is based on factors such as environmental conditions, fluid compatibility, and load requirements, ensuring the cylinder's durability and longevity in its intended application.

Customized hydraulic cylinders often incorporate specialized sealing mechanisms, such as high-temperature seals or those resistant to harsh chemicals, to meet the unique demands of the operating environment.

These cylinders are designed to seamlessly integrate with existing hydraulic systems, machinery, or equipment, ensuring compatibility and ease of installation.

Customized cylinders are optimized for performance, taking into account factors such as speed, precision, force, and efficiency to meet the specific demands of the application.

Customized hydraulic cylinders find application in diverse industries, including aerospace, marine, automotive, and manufacturing, where standard cylinders may not fully meet the requirements of specialized equipment or processes.

The design of customized cylinders can include complex geometries or non-standard shapes to fit into confined spaces or match unique structural requirements.

Manufacturers of customized hydraulic cylinders often implement stringent quality control processes to ensure that each unit meets the specified standards and performance criteria.

Safety considerations are integrated into the customization process, with features such as load holding, overpressure protection, and fail-safe mechanisms implemented as needed.

The customization process often involves a consultative approach, where manufacturers work closely with clients to understand their unique needs, challenges, and performance expectations.

Depending on the complexity of the customization, manufacturers may provide prototyping services and conduct rigorous testing to validate the performance and reliability of the customized hydraulic cylinder before mass production. In summary, customized hydraulic cylinders offer a tailored approach to meet the specific demands of diverse applications. Their adaptability, precision, and the ability to address unique challenges make them essential components in industries where standard solutions may fall short

To guarantee the reliability of the product, Bicelli Geco carries out its hydraulic cylinders internally, from beginning to end. Starting from the study of the project, till after-sales service.