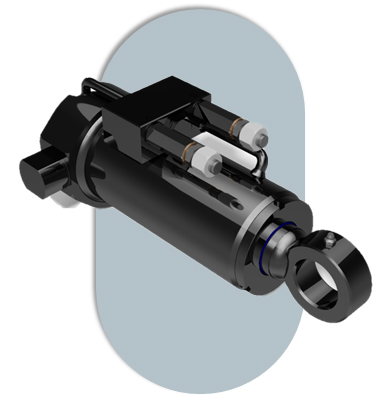

Hydraulic cylinders with damping systems integrate specialized components to control and slow down the motion of the cylinder's rod, providing controlled deceleration and preventing abrupt stops. This feature is especially beneficial in applications where precision, safety, and reduced vibrations are critical.

Hydraulic cylinders with damping systems are equipped with built-in mechanisms, such as adjustable throttling valves or hydraulic cushions, that control the rate of fluid flow and thereby regulate the speed of the cylinder's rod during extension and retraction.

The damping system ensures smooth and controlled deceleration of the hydraulic cylinder's movement, preventing sudden stops that could lead to equipment damage, wear, or safety hazards.

By controlling the speed and impact of the cylinder's motion, damping systems help minimize vibrations and shocks, enhancing the overall stability and safety of the hydraulic system.

Many hydraulic cylinders with damping systems offer adjustable damping settings, allowing users to fine-tune the deceleration characteristics to match the specific requirements of the application.

The controlled motion provided by damping systems contributes to increased precision in positioning and movement, making these cylinders suitable for applications where accuracy is paramount.

Damping-equipped hydraulic cylinders are versatile and find application in various industries, including manufacturing, automotive, and robotics, where controlled and precise motion is essential.

Manufacturers often provide customization options for bore size, rod diameter, and stroke length, allowing users to tailor the damping-equipped hydraulic cylinder to the specific needs of their application.

The controlled deceleration offered by the damping system enhances the safety of hydraulic systems, reducing the risk of sudden and unexpected movements that could pose a danger to equipment, operators, or surrounding infrastructure.

Hydraulic cylinders with damping systems are well-suited for applications with dynamic loads, as the damping mechanism helps manage the effects of varying loads on the system.

These cylinders can be seamlessly integrated into various hydraulic systems, including those used in material handling equipment, industrial machinery, and assembly lines, enhancing the overall efficiency of the systems.

In summary, hydraulic cylinders with damping systems provide controlled and smooth motion, reducing vibrations and enhancing precision in a wide range of applications. Their adaptability, safety features, and customizable options make them valuable components in hydraulic systems where controlled deceleration is crucial.

To guarantee the reliability of the product, Bicelli Geco carries out its hydraulic cylinders internally, from beginning to end. Starting from the study of the project, till after-sales service.